Keywords: Fully Hydraulic Rope Core Drilling Rig, Rock Wool Production Line

The quality of the handheld laser welding machine directly affects the overall performance of the metal laser cutting. The aging of handheld laser welding machines is an unstoppable trend. How to protect and delay aging is a key issue. Therefore, the later maintenance work is also very important.

First of all, the correct operation of the handheld laser welding machine is the basis for delaying the aging of the machine.

1. The personnel who use the handheld laser welding machine must undergo professional training, understand the purpose of the system indicator lights and buttons, and be familiar with the basic equipment knowledge.

2. Workers who use hand-held laser welding machines must check the work wire groove before work to ensure that the wiring is not damaged or exposed.

3. The external circulating water switch of the machine must be turned on before operation.

4. In the process of operating the handheld laser welding machine, if you encounter emergency situations such as water leakage, electric leakage, abnormal laser sound, etc., you need to press the emergency stop button immediately to cut off the power quickly.

5. It is strictly forbidden to place liquid objects and flammable objects on the control cabinet. The temperature in the working room must not exceed 25 degrees Celsius.

Since the laser system adopts a water-cooling method and the laser power supply adopts the air cooling method if the cooling system fails, it is strictly forbidden to start working.

6. It is strictly forbidden to touch the circuit components in the machine during work. Because when the hand-held laser welding machine is working, the circuit is in a high-voltage and high-current state.

7. Do not disassemble any parts of the handheld laser welding machine at will.

8. It is forbidden to weld during laser operation, look directly at the laser beam or reflected laser to avoid eye injury.

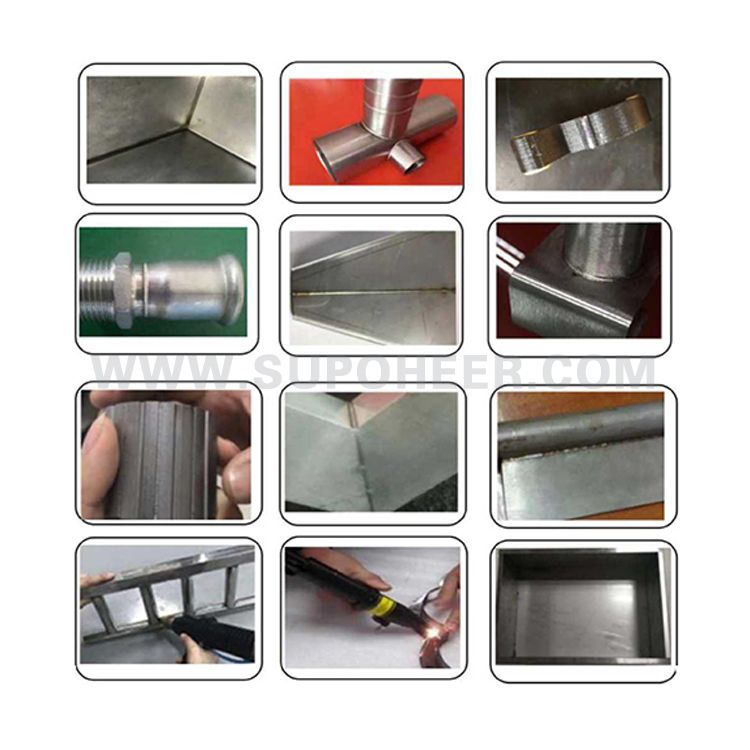

Handheld Laser Welding Machine

1. Temperature

Hand-held laser welding machines have certain requirements for the temperature of the studio. The too high temperature will cause crashes and slow response. If the temperature is too low, it will cause damage to the air pipe and cable, which may easily cause disconnection and air leakage.

2. Dust

In addition, a hand-held laser welding machine generates a large amount of metal dust during operation. However, this dust, dust, and smoke in the air will adhere to the equipment, which will increase the wear and tear between the various parts of the equipment. Dust will also affect the light transmittance of the focusing lens and indirectly affect the welding accuracy of the handheld laser welding machine.

1. Perform regular inspections.

2. Since the cooling method of the welding machine is air-cooled, it is easy to inhale the surrounding dust and accumulate inside the machine. So we can clean the dust inside the handheld laser welding machine regularly.

3. Regularly check the connection part of the line.

4. Regularly replace defective parts, repair damaged shells and repair parts with deteriorated insulation.

Maintenance work should be done well in daily work. In addition, if there is any problem with the equipment during work, it must be dealt with in time to keep the equipment in good condition.

HEBEI SUOFU TRADING CO., LTD. has the handheld laser welding for sale, if you want to learn more about it, please contact us!